耐诺铈稳定氧化锆珠(NanorZr-Ce):

耐诺铈稳定氧化锆珠(NanorZr-Ce)采用稀土氧化铈作稳定剂,全球**的电解液中高压滴定成型,中温烧结定相的工艺制成。饱满的球度和狭窄粒径分布为其外观特征,珠子的微观结构为均匀致密的四方氧化锆微晶构成,使其具有宝石般的硬度和密度,是所有锆系列磨介中*重的一种。优异的断裂韧性和超低磨耗特别适合对高固相、高磨蚀和高粘度的物料的分散和研磨。相对钇稳定氧化锆珠比较低的硬度,可以很好避免对砂磨机接触件的磨损。

氧化锆含量: 80%, 氧化铈含量: 20%,

比 重: >6.1kg/dm3, 散 重: >3.8kg/L,

莫 氏 硬度: 9, 维 氏 硬度: >1100kg/mm2,

断 裂 韧性: 15Mpa.m1/2 弹 性 模量: 180Gpa,

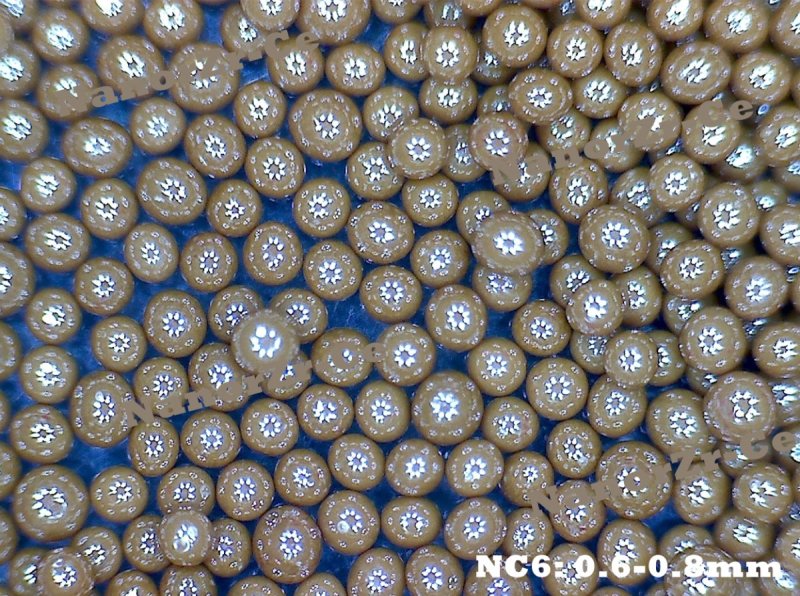

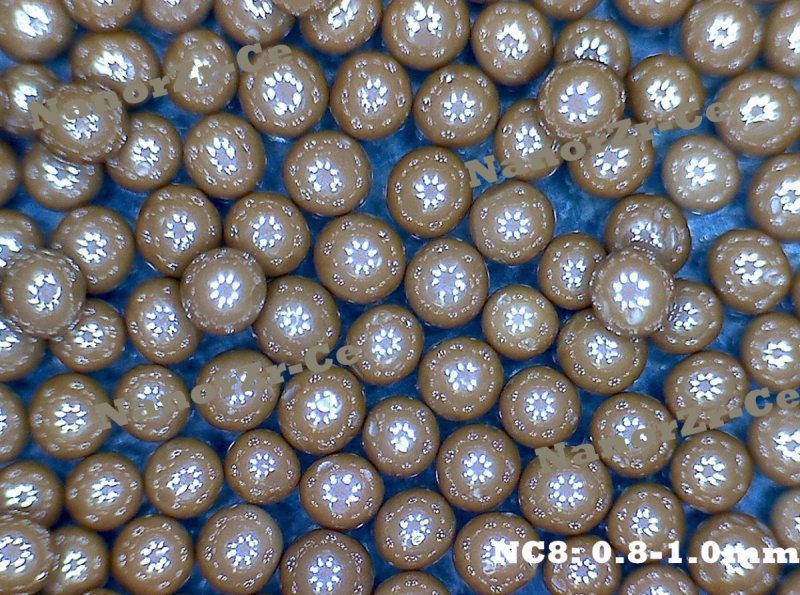

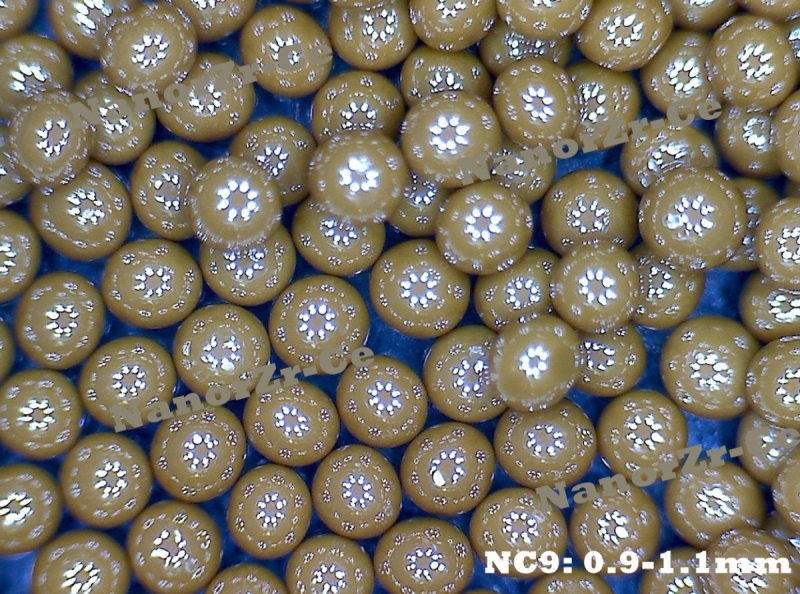

吨 磨 耗: 0.01kg/干吨, 粒 径: 0.3-5.5mm,

颜 色: 棕色, 包 装: 25kg/桶

Ceria stabilized zirconia bead NanorZr-Ce is shaped in a high pressure dropping system and sintered in a middle temperature, which is the leading manufacturing process in the world. The compact and homogenous tetragonal zirconia polycrystal result in the highest hardness,density and excellent wear resistance. It is optimal for milling high viscosity and abrasion particles in high energy intensity bead mills. Compared to the yttria stabilized bead, the lower hardness means that it protects the contacted parts of mill.

ZrO2 : 80% CeO2 : 20%

Density: >6.1kg/dm3 Bulk Density: >3.8kg/L

Hardness Vickers: >1100kg/mm2 Crushing Strength: 2000N (2mm)

Toughness: 20Mpa.m1/2 Wear Rate:<0.01kg/T

Sizes: 0.3-5.5mm Packing: 25kg/pail