DB系列·全陶瓷无污染倒钵破碎机(解碎机)

DB series · All ceramic contamination-free inverted bowl crusher (smashing machine)

工作原理:

大块物料被投入破碎腔后,会被相向旋转的特制的瓷辊上安装的大量陶瓷破碎锤头所冲击从而破碎成小块,从两辊之间落下。

working principle:

After the large pieces of material are put into the crushing chamber, they will be impacted by a large number of ceramic crushing hammers installed on the specially-made ceramic rollers that rotate oppositely to be broken into small pieces and fall between the two rollers.

设备特点:

特别适用于硬度在5级以下的大块物料、团聚块体的初步破碎和解碎,不容易产生架桥、打滑等影响破碎效率的问题。

冲击磨损部位全部工程陶瓷防护,从而满足多数高新材料避免金属杂质污染要求,包括破碎锤头、瓷辊保护套等。

可后接颚式破碎机、辊式破碎机等设备,以进一步破碎物料。

Features:

1. It is especially suitable for the initial crushing and breaking of bulk materials and agglomerated blocks with hardness below 5 grades. It is not easy to cause problems such as bridging and slipping that affect the crushing efficiency.

2. All impact wear parts are protected by engineering ceramics to meet the requirements of most high-tech materials to avoid metal impurity contamination, including crushing hammer heads and ceramic roller protective sleeves.

3. It can be connected with jaw crusher, roller crusher and other equipment to further crush the material.

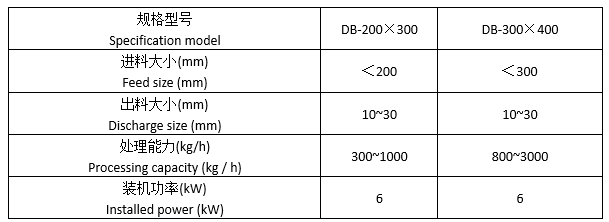

技术参数表(Technical Data Sheet):

注:具体配置及处理效果需根据物料性质与加工要求确认,可与我司工程师沟通或来料试验。

Note: The specific configuration and processing effect need to be confirmed according to the material properties and processing requirements, and you can communicate with our engineers or come todo materials processing test first.

相关**:一种防物料架桥的全陶瓷倒钵破碎机(实用新型ZL 201920290860.1)

Related patents: An anti-material bridging all-ceramic inverted bowl crusher (utility model ZL 201920290860.1)